Hypothesis Thesis:

“Loose” particles in the air handling space above the ceiling are ejected from the ventila-tion system within short time, after which the air handling space above the ceiling will no longer contaminate the air being injected into the room.

Discussion

When there is a varying volume of airflow and possible mechanical effects on parts of the air handling space above the ceiling, is it probable that this could cause a short-term effect of parti-cles being released into the injected ventilation air? When the air handling space above the ceiling is used as part of the ventilation system for clean-rooms, should the surfaces in the air handling space be cleaned for dust before closing off the system? Would this not reduce the risk of a short-term particle load to a negligible level?

Conclusion

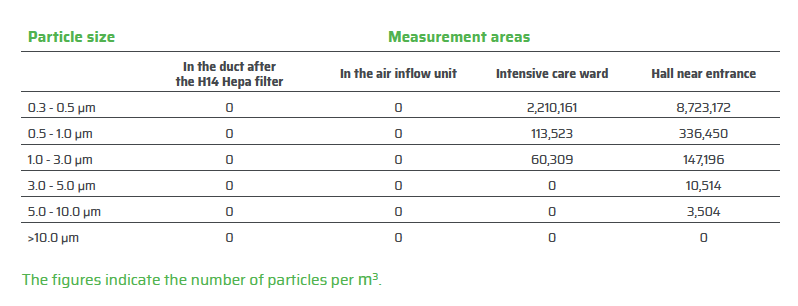

Testing showed that the air handling space does not contribute to any contamination of the ventilation air, when the air handling space is used as a pressure chamber. This is documented in the below figure.

Testing in the new mockup at OUH-intensive care ward

Testing was performed 15 September 2015, with measurements taken in- and outside the

intensive care ward, an area of about 25 m² with a ventilation rate of approx. 800 m³/h.

Room and ceiling

The room had very recently been renovated and a new and airtight ceiling from JS Koncept A/S installed. H14 filters had also been installed after the air injection Smart System. The ceiling air handling space had not been cleaned, treated with a dust control system or anything of that nature after the renovation work had been completed, so there was a certain level of particles present on the surfaces in the air handling space above the ceiling.

Filters

Nilan ventilation system type VPM 120 with built-in prefilter. After the system is a Camfil FCBS-A filter cabinet, with a built in Camfil Absolut-V H14 Hepa Filter VEXL 14 610X610X292-M. A 250 mm duct is running from the filter cabinet to the air handling space above the dropped ceiling in the intensive care ward, and this duct ends with a silencer. The air extracted from the intensive care ward, exited through two 250 mm air outlets in the ceiling, with a duct running from each outlet ending in one 250 mm duct that runs directly back to the Nilan system. The ceiling is a Smart Ceiling climate ceiling, and it is featured with four 160 mm integrated air injection units, which not are connected by ducts. During testing, there was quite a bit of construction work going on in connection with moving the walls for the mock-up. For this reason, there was a great deal of dust in the area, which affected the test measurements in the intensive care ward. However, measurements taken from the air inflows in the ceiling, show that there were absolutely no particles in the pressure chamber above the dropped ceiling or in the injection air.

Particle levels were measured in the hall at the entrance, to serve as a reference.

Measuring instrument

The particle-level testing was performed using an Aerotrak 8220 particle counter, serial number 70 910 218.